Vehicle versus pedestrian is a major cause of harm to workers and other people on work sites. If you’re looking for ways to manage site traffic and prevent accidents in your workplace, you need an effective traffic management plan.

In this article, we highlight the best methods to manage traffic and, to help you put your plan into action, we also share the best products in our traffic management range.

Traffic management in the workplace

In most workplaces, the health and safety advisor or operations manager will be responsible for creating a traffic management plan. Depending on the size of the company, the main purpose of this plan is to keep people separated from forklifts and other moving vehicles.

This protects the company by reducing vehicle versus pedestrian-related injuries or even death which is devastating for the family of those involved, and helps to avoid Worksafe knocking on the door and any downtime plus complicated health and safety paperwork that comes with a near miss or incident. It will also ensure the company does not gain an unwanted reputation for unsafe working conditions.

How to enforce a traffic management plan

1. Discussing traffic management

The first step in traffic management planning is to convey the objectives with all stakeholders. This way, you can determine the purpose behind the new health and safety measures before implementing the plan. By involving everyone in this process and communicating the value of these changes, you will maximise buy-in from everyone.

To maximise buy-in later on, you must consult with your workers and their representatives at all stages of the risk management process.

2. Identify key hazards

Next, identify any areas of the workplace that need to be managed more effectively. Each workplace will have a unique set of traffic management requirements. This will vary depending on the industry, site, what is being done, and how it is done. Key hazards and vehicle activity in the workplace usually consist of the following:

- Speed

- Reversing vehicles

- Parking

- Coupling and uncoupling

- Loading and unloading

- Driver waiting areas

- Tipping

- Load securing

- Queuing vehicles

Remember to talk to the staff who operate in your workplace and ask which areas they think need more attention. If you need support, we recommend asking the team at Health and Safety 101 to create a traffic management plan for you.

3. Create a safe workplace culture

When you implement these changes, make sure to communicate to everyone why they’re important. This is a team effort and requires a culture of safety where all employees play an active role. The key to long-term success is to involve everyone in the process right from the beginning and provide plenty of training and guidelines.

The more everyone does their part, the safer your workplace will be. As a simple first step, start by encouraging team members to wear high-visibility vests and steel cap footwear when they’re around moving forklifts.

4. Check the relevant traffic management requirements

The requirements you must follow will vary depending on your site and workplace operations. According to WorkSafe NZ, the guidelines should account for the following:

First and foremost, reducing vehicle speed and setting a maximum speed limit for your work site will reduce risks and injuries. Speed limits should be based on the workplace but should remain within industry-accepted levels. To manage speed, you can add speed limit signs and speed bumps.

However, it is worth noting that if you install too many speed bumps, it can cause frustration with drivers and frequent users. In some cases, this may lead them to find ways to avoid that route or ignore the rules altogether. While there is no clear rule for how many speed bumps to install, a few in strategic positions where speed is noted will be most effective.

5. Implement your traffic management plan

When you have a clear idea of what the key hazards are, it’s time to put your traffic management plan into action. This will involve installing bollards, barriers, and signs, and encouraging staff to wear high-vis gear in high-risk areas. Examples of traffic management requirements include:

- Speed limits

- Speed bumps or speed calmers

- Flexible pedestrian bollards

- Steel barriers

- Walkway delineators

- Traffic signs

- Road markers

- Road bollards

The most effective way to keep pedestrians safe is to provide separate routes for them. By installing pedestrian barriers, you can create clear boundaries and protect anyone from passing vehicles.

For advice tailored to your site and work, talk to our team about your situation. Depending on the number of people and equipment, we also recommend researching the range of factors that could increase risks. Once we know about these hazards, we can provide advice specific to your needs.

Traffic management solutions

Traffic management solutions vary depending on the site and the dynamics that operate within it. To start with, we’ve highlighted our best product management products below:

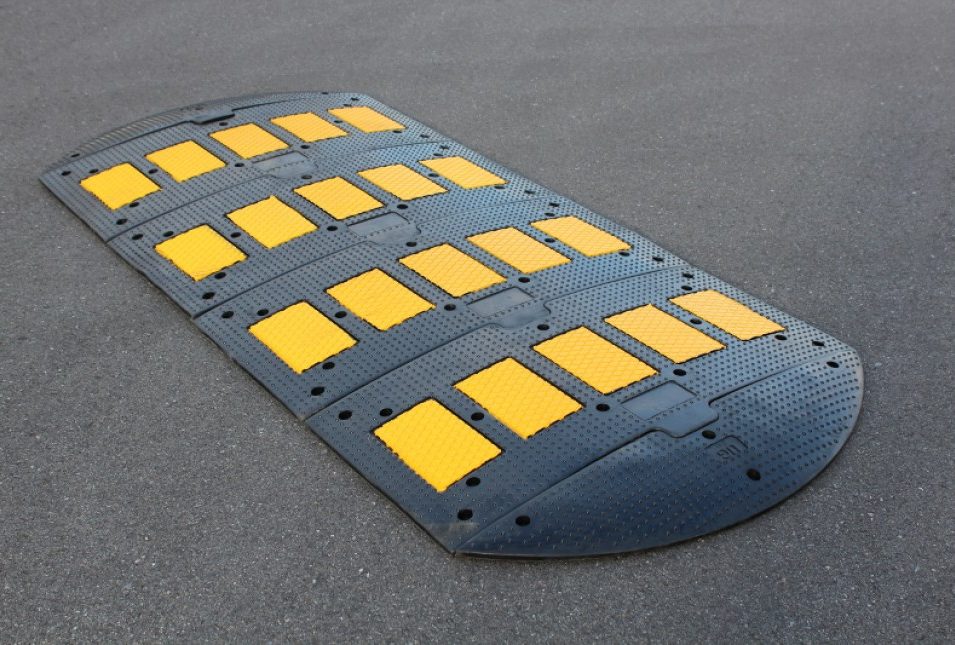

1. 75mm Speed cushions

Our 75mm Speed Cushions are designed to slow traffic on access routes used by both cars and trucks. The longer profile is more lenient on larger vehicles and is effective at slowing cars, utes, trucks, and buses. This also spreads the vehicle weight across the ground, making it a more durable option for industrial areas and heavy traffic.

- Slow cars and trucks in shared areas

- Convenient interlocking system can be configured to any length

- Can be relocated if required

- Middle sections feature hi-vis yellow panels

- Forklift-passable

Discover the 75mm Speed Cushions here.

2. 50mm Speed cushions

Our 50mm Speed Cushions are designed to slow vehicles in heavy traffic areas. The speed cushion disperses the heavier weight load and also allows forklifts to pass, which is ideal for many workplace environments.

- Convenient interlocking system can be configured to any length

- Can be relocated if required

- Middle sections feature hi-vis yellow panels

3. Tru-Gard Double-Rail Barrier

The Tru-Gard double rail barrier is 910mm high and made with certified steel. Designed to protect personnel and buildings from forklift damage, these barriers are robust and offer a higher strength rating than many others. Depending on your needs, the bottom rail can be placed 100mm off the ground or at ground level for protection against fork tines.

- The modular system can be configured to suit your site.

- Post centres of 1.1m maximises impact absorption.

- The 910mm high double rail can stop 7T moving at 6.3km/h.

- Compliance with AS/NZS 1170.1 Section 3.8.

- An optional pedestrian handrail can be mounted to the barrier.

Discover Tru-Gard Barriers here.

4. d-flexx Pedestrian Barrier

The d-flexx barrier range is a certified, shock-absorbent, and highly impact-resistant safety barrier designed to separate pedestrians and high-traffic areas. This pedestrian barrier consists of three pedestrian rails, creating a simple yet robust partition between walkways and areas where light vehicles or machinery are operating.

- Made from a flexible, impact-resistant PE polymer

- Absorbs impact and returns to its original shape

- 100% recyclable

- UV-resistant and suitable for indoor and outdoor use

- Pedestrian Barrier stops 2T moving at 5.7km/h

- Tested and certified by German TÜV NORD

- Exceeds AS/NZ 1170.1:2002

- Other configurations are available with greater impact resistance.

Find out more about d-flexx here >

For more information about traffic and pedestrian safety solutions, and the best methods for protecting your workers, contact the team, browse our products or download the Worksafe Good Practice Guide.